Service

Play it safe

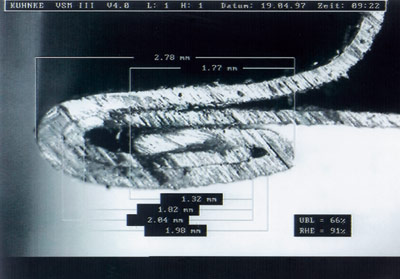

We offer our customers the opportunity to check the settings of the seaming rollers using a seam image inspection. To avoid swelling and faulty seaming, seam inspections are indispensable. In this, the wear of tools and seam changes are detected early, before any damage occurs.

Based on your empty, seamed can we provide you with a computer precise seam image inspection. Naturally, you will receive a printout of the findings for your documentation.

Get your cans checked regularly, so that you can always be sure that the seaming is proper and tight.