Products

Measuring tools & Accessories

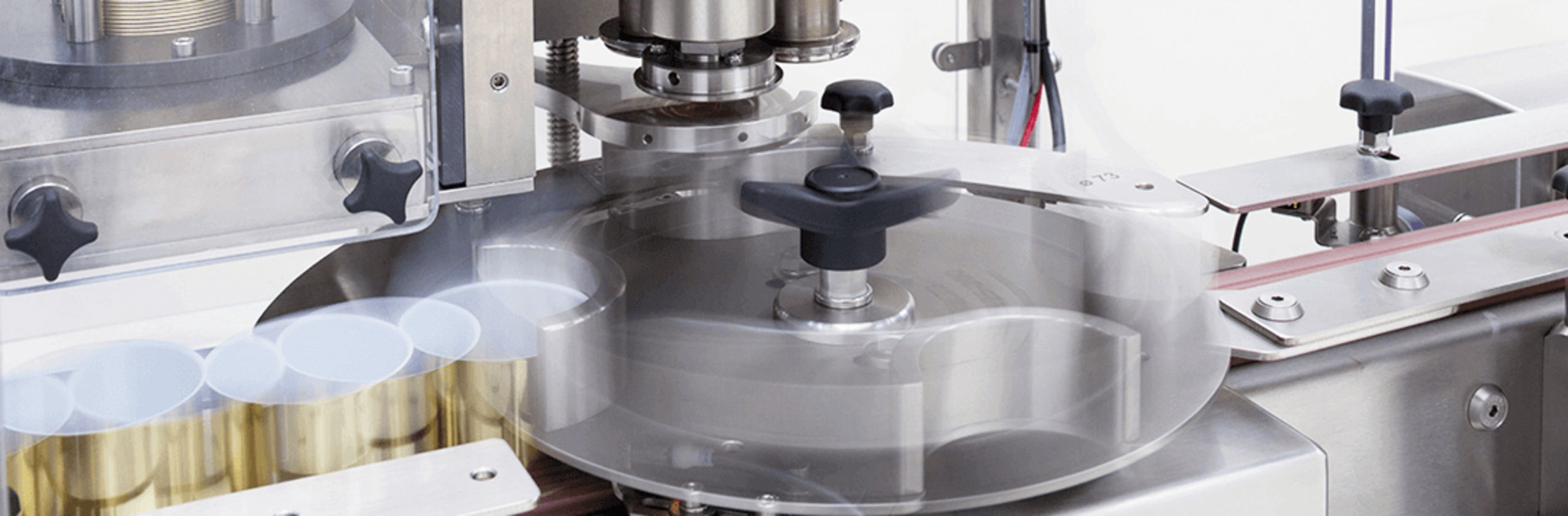

In order to meet the high quality standards, it is necessary to work with a correctly adjusted can seaming machine matched to the material or product. Here it is crucial to work with the right tools. To ensure consistent quality, leak tests, seaming inspection and a possible readjustment are indispensable.

Our services include, among other things, the leak test in the form of seam image inspection. Based on your empty cans, seamed can samples, we create a computer precision seam inspection with documentation for your records.

To enable you to perform various tests independently, various measuring and adjustment tools are required.