Products

Product Video

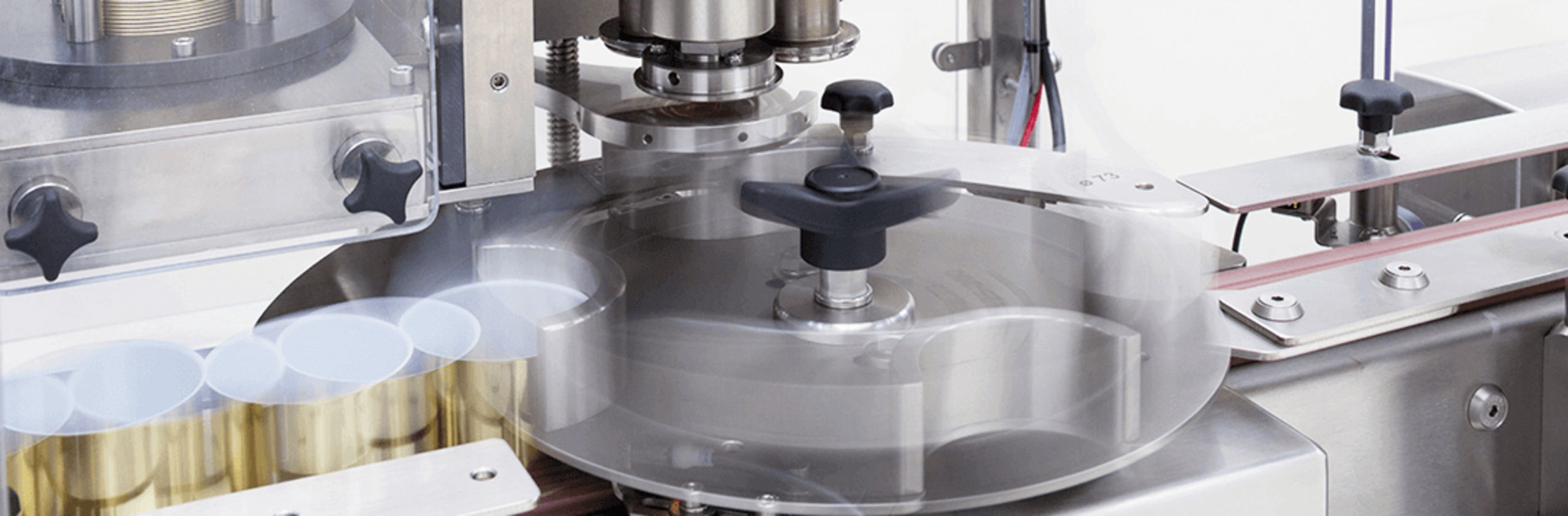

format change STA 1200 D

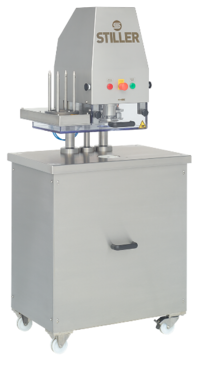

Can Seaming Machine STA 1200 D

With automatic lid feeder

Sophisticated, semi-automatic can seaming machine in stainless steel for use in butcheries, laboratories, wet and dry undertakings. Suitable for seaming round tin cans and composite cans.

The STA 1200D features an automatic lid feeder with separating magazine.

Technical data

| Capacity: | max. 1000 cans/hour |

| Rec. annual capacity: | max. 200.000 cans/year |

| Diameter: | 52 – 99 mm |

| Height: | 30 – 300 mm |

| special sizes on request | |

| Power supply: | 0,75 kW, 3 x 400 VAC+N+PE / 16 A / 50Hz |

| Dimensions: | 80 x 50 x 170 cm |

| Weight: | 235 kg |

| Air consumption: | approx. 4,4 m³/h at 6 bar Acc. to ISO8573-1:2010/7:4.4 (Compressor not included) |

Technical advantages

- Sophisticated design made of non-rusting material

- Suitable for wet and dry undertakings

- Constant working height

- Flexible working by automatic height adjustment

- Automatic, standstill clamping and unclamping of the can

- Electrically controlled seaming process

- Easy and safe operation thanks to two-hand safety control

- Quick format change by simply changing the format parts

- Large, maintenance-free seaming

- Flexible use through transport rollers

- High performance

- Large range of sizes

- Fully automatic lid feeder with separating magazine

Operation

The can is placed without the lid on the base plate and the seaming process is initiated with the two-hand safety control. This lifts can, the lid is picked up; both are set into rotation and seamed.

After the seaming process the can is stopped and lowered at standstill. Simultaneously on lowering the can also the next lid is slid under the seaming chuck.

Our recommendation for you

We recommend that you perform regular leak tests using our proven can inspection pump. It can be used for all common types of cans.

If you need a machine for large casks up to ø156 mm, we offer you a suitable solution: Our STA 1200 DG - specially designed for larger formats.