Products

Technical data:

| Capacity: | up to 1.500 cans/hour depending on product and can size, reduced capacity for liquids |

| Rec. annual capacity: | max. 500.000 cans/year |

| Diameter: | 52 – 99 mm |

| Height: | 30 – 200 mm other dimensions on request |

| Power supply: | 0,95 KW, 3 x 400 VAC+N+PE / 32 A / 50Hz |

| Dimensions: | 200 x 80 x 180 cm |

| Working height: | 100 cm |

| Weight: | approx. 380 kg |

| Conveyor: | Standard |

| Air consumption: | approx. 3,75 m³/h at 6 bar Acc. to ISO 8573-1:2010/7:4.4 (Compressor not included) |

Technical advantages:

- Sophisticated design made of stainless material

- Suitable for wet and dry undertakings

- Hygienic and easy to clean/li>

- Flexible working by automatic height adjustment

- Constant working height

- with adjustable speed for indexing star wheel

- wih swivel system for operator panel, to operate the machine from the front and back

- Fully automatic can and lid feed

- Standstill clamping and unclamping of the can

- Large, maintenance-free seaming rollers

- Short conversion times for format changes by simply changing the format parts

- Wide range of sizes

- Easily movable thanks to 4 castors with brakes

- Siemens PLC controller with text display for error messages

- Stainless steel cabinet

Functional description

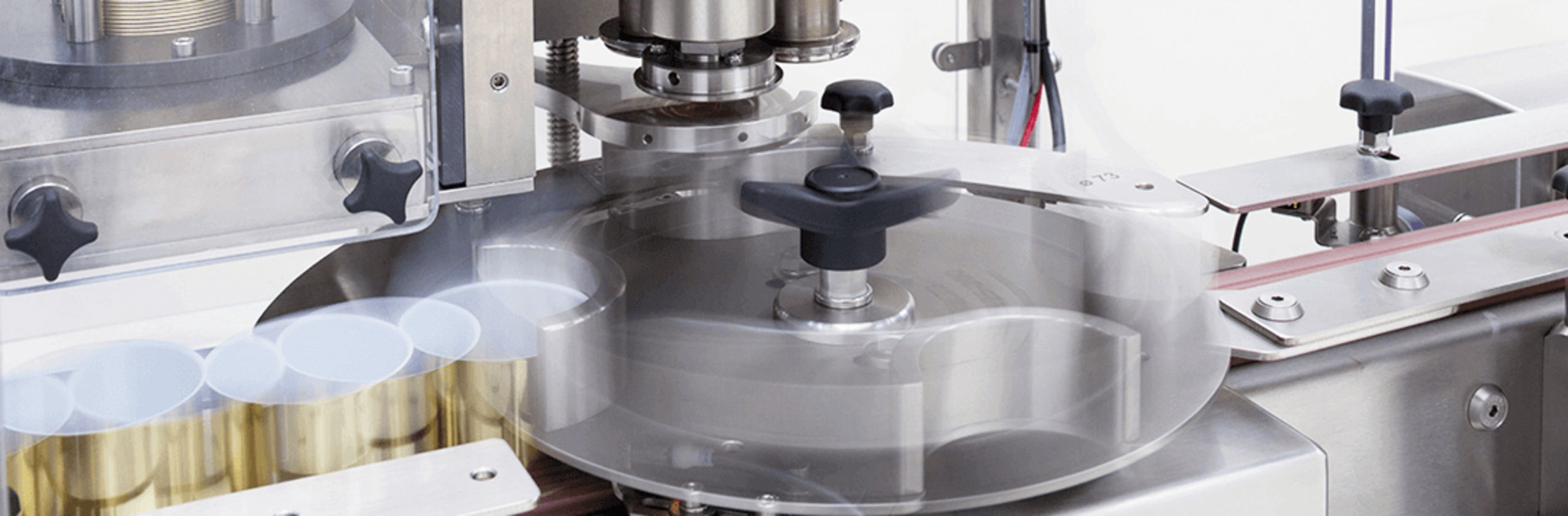

The filled can is fed to the machine by the conveyor belt. An indexing star picks up the can and feeds it to the seaming station. Simultaneously, a lid is stacked from the magazine and positioned under the sealing station. The can is lifted there, the lid picked up and both are pressed together against the seaming chuck. Only now the can is rotated and seamed with the seaming rollers mounted on a lever system airtight and reliably. Thereafter the can is stopped, clamped out and the indexing star passes the seamed can back to the outfeed belt.

Format change

When changing the format, the seaming lever is changed completely with the ready set seaming rollers, which makes setting the seaming rollers redundant. Replacement of the seaming chuck, the lid magazine, the can guides and the indexing star is simple and largely carried out without tools.

Switching to another can height is done manually by adjusting the height of the machine head. Using quick-change format parts guarantees a format change within few minutes, which results in only short immobilization of the machine.

Automatic height compensation

By using special format parts, the cans can be seamed with a height difference of up to 30mm WITHOUT having to adjust the machine. You can seam, for example ø99 / 200 - 400gr cans or ø73 / 125 - 200gr cans without having to adjust the height intermittently. The height adjustment is automatic.