Products

Cleaning equipment

Cleaning systems are available in different variations for empty or full can cleaning with hot steam, water or air.

For example, blow cleaning, steam cleaning or spraying machines are available.

Blowing machine Type “TYPHOON”

For blowing out of composite cans with recirculating air

- Stainless version, with continuously variable star insertion device,

- Set up for a cask size

- Capacity: 60 cans/minute

The cans/jars are driven by a special rotating basket in the pile up, where they perform a total rotation of 360 degrees.

With an average capacity of about 60 cans / jars per minute the rotating basket is designed so that the cans / jars run over a distance of 400 mm with the outlet downward over an air nozzle and are blown with recirculating air.

The intake air is filtered through a dust bag.

The machine is equipped with push-in station, infinitely variable and a turning basket for a can size.

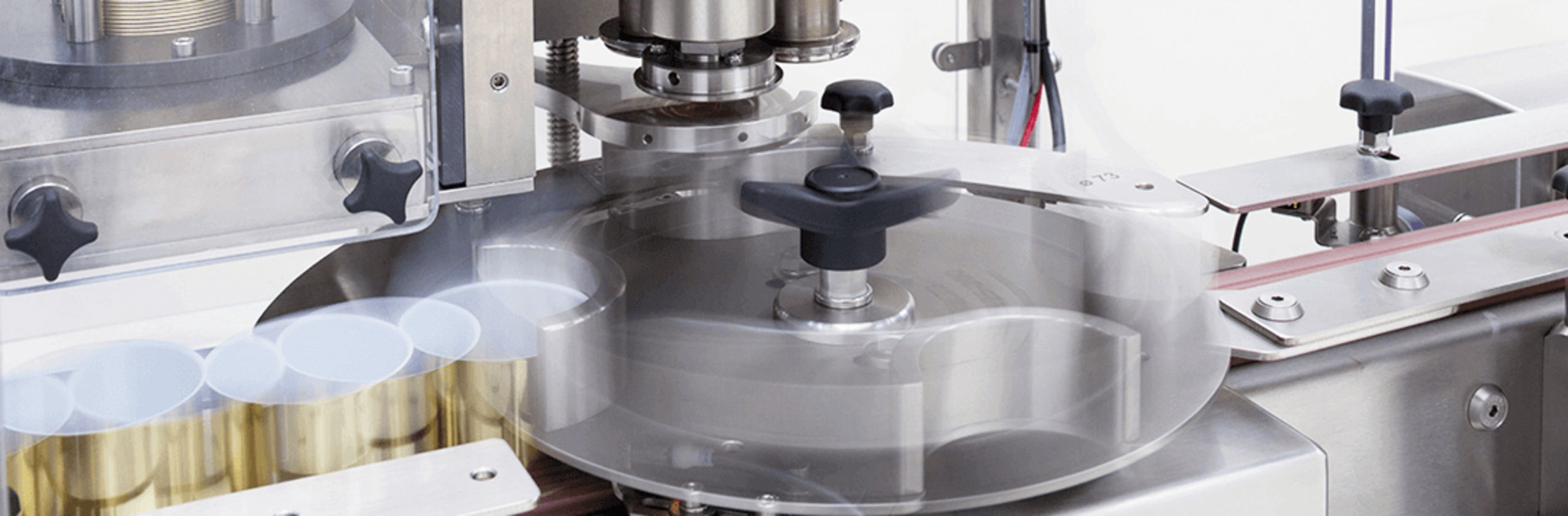

Steaming / Spraying machine Type “TYPHOON”

For steaming or rinsing of cans with steam or water

- Closed stainless steel housing

- Equipped with spraying stick and turner incl. infinitely variable star insertion device in stainless steel design

- Capacity: 3000 cans/hour.

The steaming/spraying machine consists of a self-supporting stainless steel casing, the lower part of which is formed as a tub. The cans/jars are driven in the pile up through a special rotating basket, where they perform a total rotation of 360 degrees. The rotating basket is designed so that the jars/cans run for a distance of 400 mm with the outlet downward over a nozzle and are flushed with hot water or steam. Finally, the casks pass through a drip line of about 200 mm before they are again rotated 180 degrees with the cask outlet upward.

The machine is equipped with push-in station, infinitely variable and a turning basket.